Mit Anwendern entwickelt

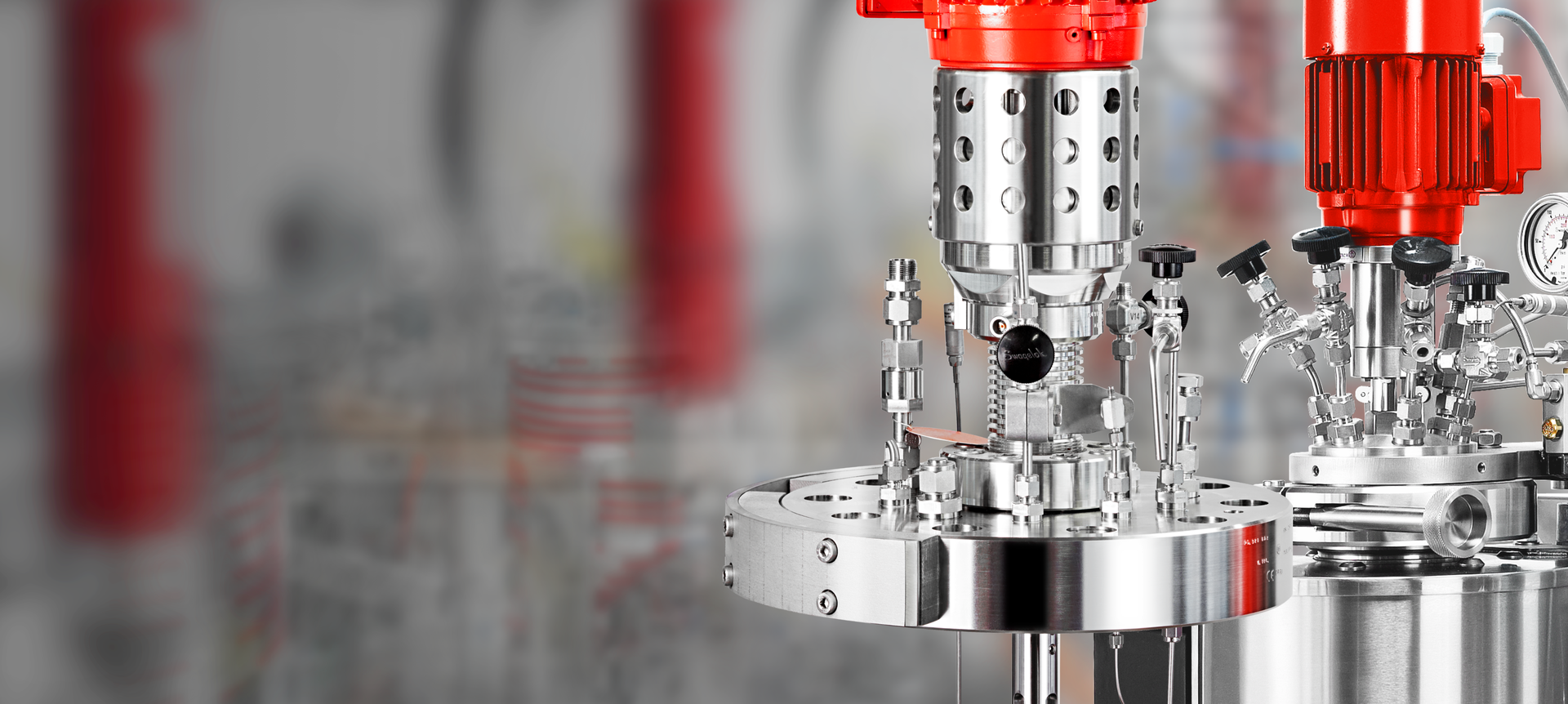

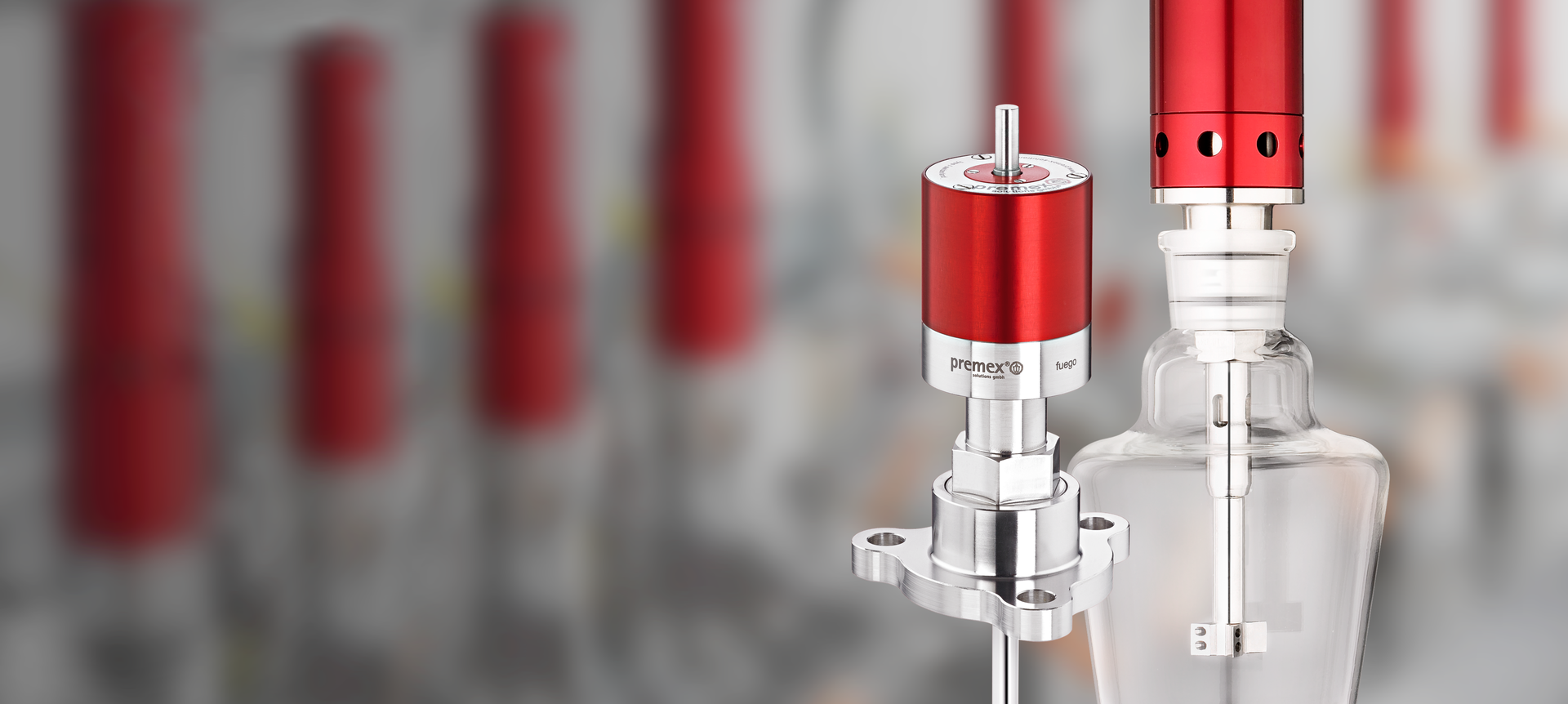

Magnetrührer

Mit unseren vielseitigen Baulinien decken wir nahezu jedes Kundenbedürfnis ab.…

mehr lesenHochdruckreaktoren

Die premex solutions gmbh konzipiert und fertigt Hochdruckreaktoren für den…

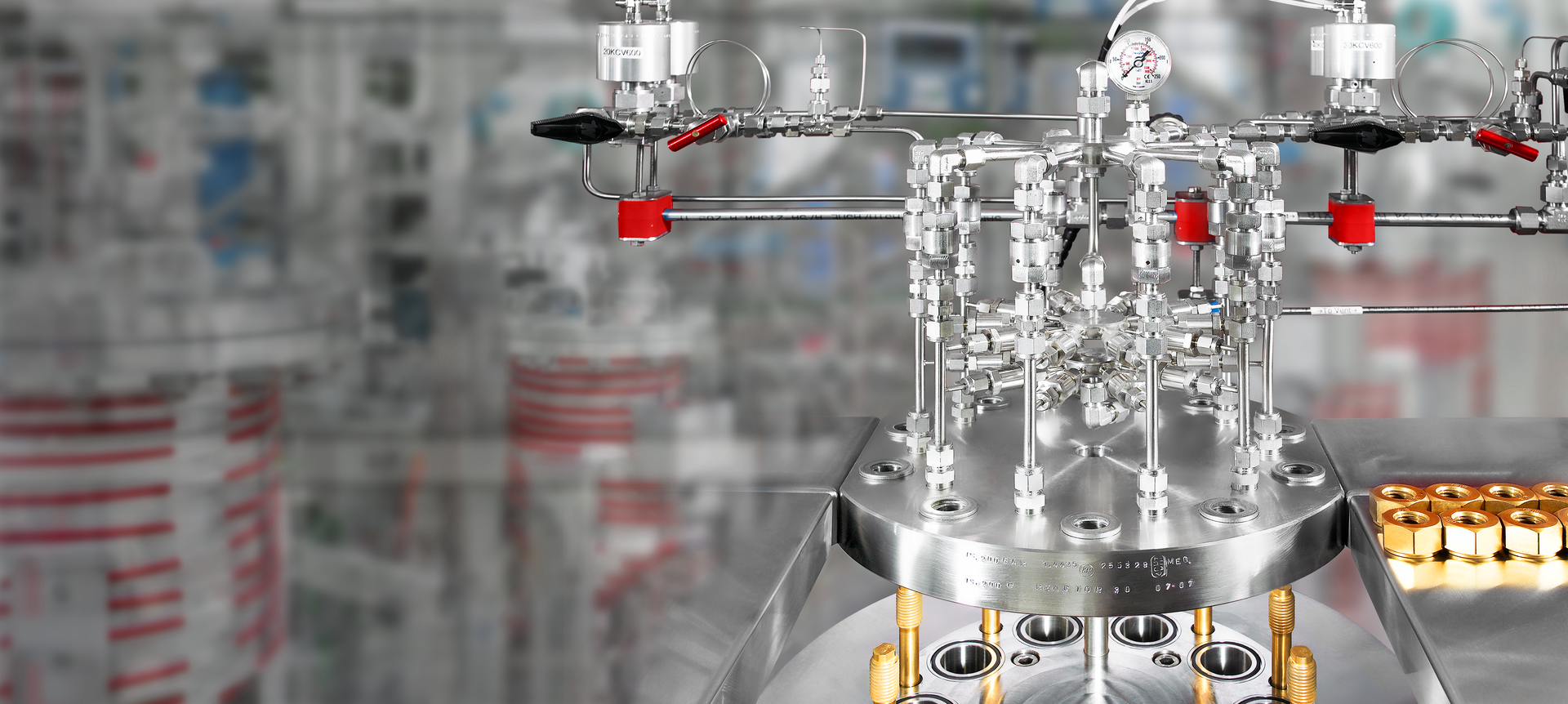

mehr lesenVerfahrensanlagen

Wir geben Ihnen massgeschneiderte Systemanlagen an die Hand für Forschungen in…

mehr lesenSteuergeräte

Zur Ansteuerung und Regelung unserer Hochdruckreaktoren liefern wir Ihnen von…

mehr lesenZubehör & Ersatzteile

In dieser Rubrik bieten wir Ihnen Peripherie-Geräte für Ihre Hochdruckanlage,…

mehr lesen

Neues wagen, Bewährtes voranbringen

Eine Marke die für sich spricht "premex"

Durch das in der Unternehmung verankerte Know-How und die langjährige Erfahrung auf dem Gebiet der Hochdrucktechnik, gehen wir in der Branche mittels Entwicklungen und Produktverbesserungen neue Wege und setzen immer wieder Massstäbe und Standards.

Mehr InfoDen Herzschlag der Branche spüren

Pharma, Aroma & Duftstoffindustrie

Synthese von Feinchemikalien & APIs, (unter anderem mit Hydrierung), werden…

mehr lesenChemie & Petrochemie

„premex“ Produkte werden bei der Entwicklung von neuen Materialen, Katalysatoren…

mehr lesenChemie & Agrochemie

Wir tragen zur Entwicklung von neuen Produkten und Verfahren bei mit Autoklaven…

mehr lesenEnergie & Ölindustrie

Bei der Herstellung von Kraftstoffen und in Themen der Energiewende werden…

mehr lesenPolymer Industrie

Wir bieten Autoklaven und Versuchsanlagen für die Polymerforschung in der Gas-…

mehr lesenAutomobilindustrie & Abgasreinigung

Wir bieten Lösungen im Benchmarking, Qualitätssicherung und Entwicklung von…

mehr lesen

Was wir bieten - wovon Sie profitieren

Wir begleiten Sie bei jedem Projekt von der ersten Idee, der Konstruktion und Fertigung bis hin zur geprüften Abnahme FAT und After Sales Service. Sie erhalten bei uns alles aus einer Hand. Wir sind in der Lage massgeschneiderte Lösungen anzubieten, die genau Ihren Reaktionsprozessen entsprechen. Sie haben auch die Wahl eines Standardsortiment, dass sich modular ausbauen lässt.

Mehr InfoShowroom

Jetzt Virtuellen Showroom entdecken!

Unsere Magnetrührer und Hochdruckreaktoren haben ihren Auftritt im online Showroom. Sie navigieren sich ganz einfach durch unsere Produkte, rufen Kenndaten ab an Infopunkten, verlinken sich auf die Produktseiten oder erfahren mehr über unsere Leistungen per Videos.

Innovation heute - für die Welt von morgen

Sie erfahren … in welche Prozesse unsere Kunden investieren und was für Lösungen wir bereithalten, … an welchen Fachmessen und Symposien Neuheiten erscheinen, … von Forschungsgebieten, die uns die Zukunft weisen, … wie Sie durch unsere Vertretungen weltweit betreut sind …

56. Jahrestreffen Deutscher Analytiker in Weimar vom 15. - 17. März 2023

Das Deutsche Katalysetreffen geht in die nächste Runde - kommen Sie zur 56.…

WeiterlesenHochdurchsatz- und Parallelreaktorsysteme

Die Systeme mit mittlerem und hohem Durchsatz sind so konzipiert, dass die…

Weiterlesenpremex solutions ist Teil der AGI-Gruppe Wir freuen uns!

AGI Group expandiert in den Markt der Hochdruckchemie mit der Übernahme der…

Weiterlesen